- Home

- Kasa's Part in Automation – Our Capabilities

- System Integration

- Utility Management

Utility Management for Industrial & Manufacturing Facilities

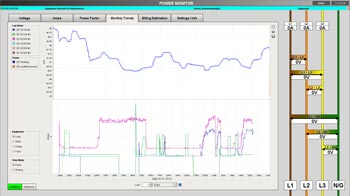

If you could cut your utility expenses by 1 to 5%, what would that do to your bottom line? Many companies and facilities are realizing that a key to cutting their utility bill is to monitor and control their peak demand and power factor. Limiting peak demand helps decrease your electric bill significantly!

The two keys to reducing peak demand are:

- to predict when a new peak level is established

- efficient control of electrical equipment

For example, your utility company charges for the HIGHEST AVERAGE fifteen-minute demand period for the month. You have multiple pieces of equipment that operate at full load periodically throughout the day. Staggering the start and run-time of equipment reduces the peak demand, which can be performed automatically. Read more about usage and peak demand.

One customer was able to significantly reduce their utility costs by timing the start-up and run-time of multiple pieces of equipment. This customer also knew the times of day that energy costs were higher and scheduled his equipment to run before and after those times when it was possible.

Improving Power Factor

Improving power factor is the next key to save on utility bills. For most facilities, the first step is to determine their power factor by equipment or service entrance. Kasa software can capture this data and log it, thus allowing a facility to determine when and where they can improve. Often additional capacitor banks can help improve the power factor measures.