Inventory Tracking & Recipes

ERP Inventory Integrated with Plant Floor Inventory

Is your plant floor constantly connected to your raw material inventory?

Have you ever started a product run, only to run out of inventory before the order was fulfilled resulting in downtime?

Connecting your operational system to your inventory system can minimize these mishaps. REPCO® improved their inventory accuracy when they replaced their RS Batch system. Review the case study to learn more.

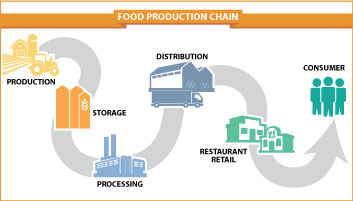

Source to Destination Traceability

Do you require source to destination traceability due to food safety potential recalls?

We’ve designed systems that deliver source to destination traceability for grain and food facilities and are able to interface to other legacy systems to preserve your current system while speeding up operations.

We’ve designed systems that deliver source to destination traceability for grain and food facilities and are able to interface to other legacy systems to preserve your current system while speeding up operations. Do you require tracking and logging of production data for highly regulated manufacturers like military or aerospace? Kasa has performed a number of projects tracking anodizing and finishing process data.

Recipes Improve Quality in Manufacturing

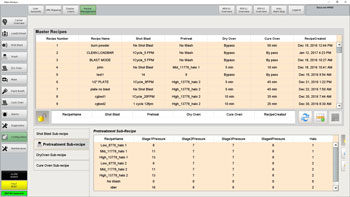

Frequently, manufacturers produce a variety of products with unique specifications or formulations. These specifications and formulations are saved as "recipes" into the SCADA or MES systems for deployment, optimization and execution on automated equipment. A recipe-driven system simplifies operator usage and improves quality.

The image at the right is an example of data that is available in a paint facility developed for an IntelliFinishing project. For this company, the amount of time that a part is in each of the stages is critical to quality and specific to that type of part. Our system loads this recipe into the software. The recipe automatically adjusts every piece of equipment, as well as, the conveyance speed specifically for the part being processed.