A large aerospace manufacturer replaced their obsolete Pyramid Integrator PLC-5/250 Controller. The use of Kasa’s expertise was instrumental in keeping the system downtime to a minimum.

The project included:

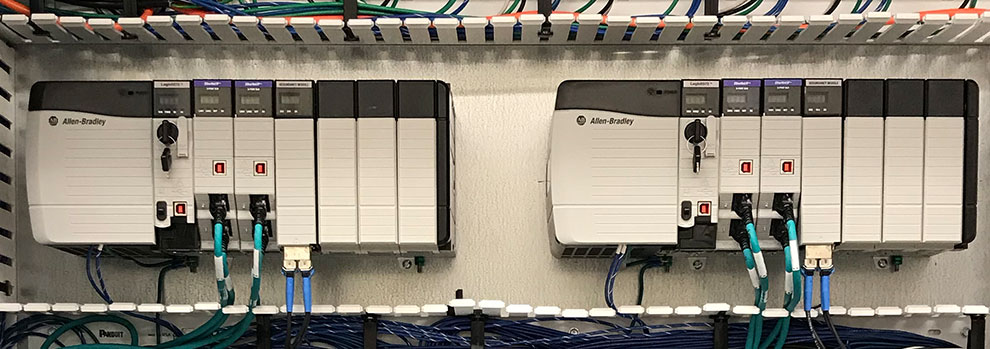

- replace PLC-5/250 Controller

- clean up and conversion of the Power & Free program

- develop “On-Shift” testing environment

- clean up previously converted software (ASRS, process equipment and material handling system)

- integrate previously installed monitoring system into current system

Reduce Amount of Production Downtime

This high priority aerospace project came to us as a result of the OEM’s inability to perform the project. When the OEM projected an eight-month shut down, we were contacted to see if we could perform this project in a time-frame that was more suitable to the manufacturer.

Kasa was hired to finish the conversion of Pyramid Integrator system without affecting production. If we failed, the customer’s loss in productivity would have been catastrophic.

Open discussion of schedules were a regular occurrence during this PLC conversion. We worked with our customer and took advantage of their scheduled downtime and holidays. We completed the project with minimal downtime.

Parallel Testing of Code Ensures Smooth Conversion

Our customer stated that some of the code involved in this project was so massive that even their own personnel had not actually seen some of it, since it was implemented more than twenty years ago. “Kasa engineering staff took the initiative to understand code that we did not even understand, and successfully designed a system to compare the original code with the converted code for the new system.”

“With their understanding of the old code, the Kasa team identified many corrections that had to be made in the new code before it would mirror the old code. The team’s efforts and level of professionalism gave us the confidence that the project could be completed,” said the project manager.

“Kasa initially presented a plan that gave us a feeling of confidence; and proceeded to carry it out. Kasa identified many areas that reflected the previous vendor’s lack of confidence. Though we did not complete the conversion during the initial attempt (with the original contractor), we had a strong feeling that it could be completed this time, regardless of the earlier conclusion that the conversion could never be accomplished!”

To learn more about how Kasa might be able to elevate your PLC operations, contact us today.