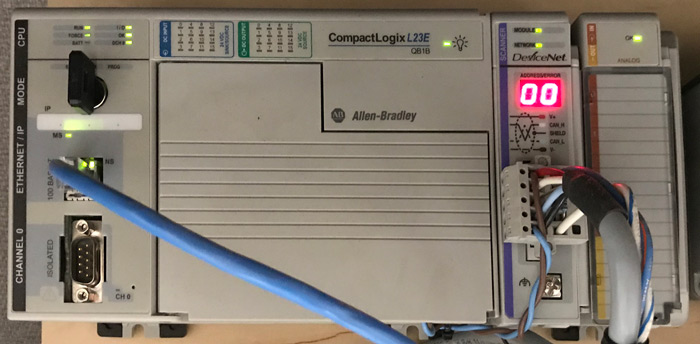

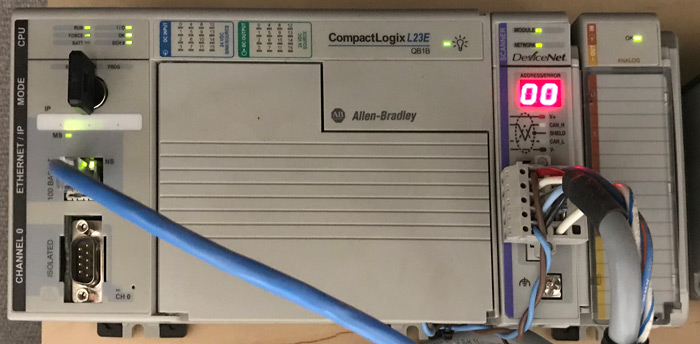

Automation systems can be quite complex, but they are typically controlled by a Programmable Logic Controller (PLC). A PLC is a digital computer designed for rugged industrial applications and is the “brains” of a manufacturer’s automation system. Typically used in control panels to perform the logic processing, PLCs implement programs written by the user to determine how a machine or process operates, controlling those that necessitate high-reliability control, ease of programming, and process fault diagnosis.

The History of PLCs

PLCs were first developed for the automotive industry to provide a flexible alternative to hard-wired relays, timers, and sequences. Today, PLCs have evolved in pace with technology to be used in a variety of harsh manufacturing settings, controlling processes that include assembly lines, robotics, and more, producing output results in response to real-world input conditions within a limited time.

Benefits of a PLC

A PLC program is in a constant state of analysis, monitoring inputs from sensors on the equipment and turning on and off outputs as needed to control process equipment. A PLC can assess and record important data such as throughput, notify users if the equipment malfunctions, and can automatically start or stop the equipment based on a predetermined schedule. Handling a wide range of communication protocols, PLCs communicate seamlessly with numerous systems to provide optimized flexibility, including the rapid export of data to supervisory or data acquisition systems. Another advantage of PLCs is their scalability. While each PLC only has a finite amount of memory, these systems can integrate an extensive amount of data. Further, PLCs allow users to add new features easily.

And unlike lab or personal computers, PLC installations are built for industrial environments, boasting long lifecycles to provide reliable equipment control for many years, regardless of conditions. These installations provide great tolerance of heat, cold, dust, and vibrations found in industrial environments.

The use of programmable controllers also provides an added layer of advantages to PLC functionality:

- Very fast to use

- Easy to change logic

- No moving parts means better reliability

- Low power consumption

- Simple to maintain modular assembly

- Facilitates in fault finding and diagnostics

- Handles very complex logic operations

- Excellent documentation of facility activity

- Couples easily with process computer

- Analog signal handling and closed loop control programming

- Programmable counter, timer, and comparator

- User-friendly operator interface

How to Choose the Right PLC

When choosing a PLC, multiple factors can impact your organization’s automation. Each element must be carefully considered to ensure the reliable, flexible and seamless functionality of your unique processes.

- Memory size

- Input and output capacity

- Processing speed

- Networking capabilities

- Ease of programming

- Field support available

- Cost

These factors can be both overwhelming and perplexing to assess, with each requiring specialized knowledge that only the right partner can provide. That partner is Kasa Controls—your one-stop-shop for PLCs.

The Kasa Difference

At Kasa, we have evolved the PLC installation. Older PLCs only have the ability to do one thing at a time. Thus, it would take multiple steps to first scan inputs, apply the logic program, and finally set outputs. Kasa’s PLC systems are different. They can include the basic logic problem solving of early PLC equipment but are rugged multicore machines with high-threading processors, similar to what is found in a standard laptop.

With this increased capability to use multiple programming languages, in addition to the traditional ladder logic used by older devices, our systems can do more. They can simultaneously run multiple programs and routines, scan inputs and outputs, and communicate with other devices. With real-time production data collection, users can make timely business decisions, identify product defect rates, and collect empirical data for making process improvements. Savvy businesses can improve efficiencies dramatically.

At Kasa Controls, our technically innovative team consists of design technicians and graduate level engineers boasting extensive backgrounds in a variety of programming and engineering fields. We have the experience and expertise to help propel your facility’s automation. Find out how our PLC support is different by contacting us today.