With an estimated 4.5 billion air passengers in 2020, air travel is a cornerstone of modern transportation, connecting people and cultures across the world. However, behind the scenes, the efficiency of airport operations depends greatly on baggage handling systems’ (BHS) reliability and functionality. Many airports, especially those with older infrastructure, have been grappling with outdated BHS that often lead to bottlenecks, delays, and frustration for both passengers and airport staff. One such airport seeking a transformative solution is Honolulu’s Daniel K. Inouye International Airport (HNL), where Kasa Controls and Automation is undertaking a first-of-its-kind BHS project.

Redefining HNL’s Baggage Handling System

The scale of the project — with an expected completion later this year — is ambitious and encompasses various areas of the airport. Kasa’s role extends to providing a state-of-the-art distributed outbound system for Hawaiian Airlines in Terminal 1 and for United Airlines in Lobby 8. The project also involves modifying, refurbishing, and equipping lobbies 4, 5, 6, and 7 in the original architecture of the airport.

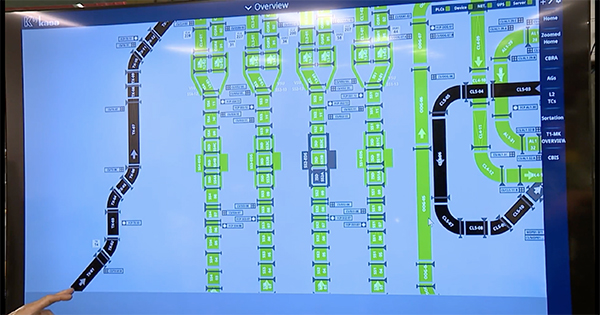

From the very beginning, Kasa embraced innovation to propel the airport’s technology forward. Departing from the traditional centralized systems that have been in place for decades, Kasa designed a unique, distributed architecture, bringing technology into the field directly onto the equipment, making it more accessible, modular, and easier to maintain. This architectural innovation — while enhancing the system’s complexity — significantly increases the airports value proposition and positively influences customer perception.

Thus far, Kasa has provided all the electrical equipment and controls programming, which contributes to the project’s technological foundation. To ensure the best outcome, Kasa joined forces with other industry expert vendors to ensure the perfect solution is delivered, including:

- Nan, General Contractor

- Five Star Alliance, Mechanical Conveyor Contractor

- Wasa Electrical Services, Electrical Contractor

- BNP Associates, BHS Consultant

Overcoming Unique Challenges

As pioneers of this new architecture, Kasa has remained flexible in adapting to unforeseen challenges encountered throughout the project. One of the significant obstacles involved a substantial alteration in the selection of drives — a departure from the original bid. This shift required Kasa to embrace a new type of motor and drive that had not been utilized in previous projects. Despite this unexpected change, Kasa’s engineering team ensured the proper control and seamless implementation of the new components through thorough testing and collaboration.

Another learning experience was the BNP certification process. Kasa navigated the complex landscape of the certification, gaining invaluable insights for future airport BHS updates. This project marked the first time that Kasa had to accurately track bags through a large system, integrating seamlessly with third-party equipment like L3 EDS machines. The complexity of L3 EDS machines posed a unique challenge, akin to distinguishing a moped from a Mercedes Benz in terms of intricacy.

Furthermore, Kasa extended their capabilities to upper-level controls, a task that had been undertaken for smaller projects in the past. However, the Honolulu project marked their foray into implementing these controls on a grand scale. What’s more, the team also experienced unexpected material delays exacerbated by the fallout from the COVID-19 pandemic. These delays impacted various aspects of the project, from design to installation, putting Kasa’s engineering prowess to the test. The delays prompted Kasa to adapt, finding temporary solutions to keep the project on track while overcoming obstacles.

So far, this project has served as a testament to Kasa’s unwavering commitment to critical and innovative thinking, a value that we are proud to consistently uphold.

A Bright Future for Airport Efficiency

Despite the encountered challenges, a monumental accomplishment was marked when Terminal 1’s new Baggage Handling System (BHS) was activated. This achievement held profound significance for the team at Kasa, particularly due to the implementation of the completely novel architecture. The transition was orchestrated flawlessly, signifying a seamless shift from the old system to the innovative Kasa Kontrol Studio system. Remarkably, as Terminal 1 became operational, the cutover occurred ahead of schedule and with no flight delays. In fact, the team’s efficiency was so pronounced that the airlines were yet to commence their baggage checks as Kasa’s preparations outpaced their operations!

Prior to the cutover, there had been an air of skepticism, half-expecting Kasa to encounter many difficulties. However, the flawless cutover shattered these doubts and significantly transformed the perception of Kasa’s capabilities. The collective efforts of the team had defied expectations and turned a potentially nerve-wracking event into a resounding success.

Finishing HNL’s New System

While the successful launch of Terminal 1’s baggage handling system marks a significant achievement, the journey towards enhancing the Honolulu Airport’s operations is far from over.

Kasa is gearing up to embark on the next phase, which encompasses the replacement of additional baggage handling systems across the entire airport. This expansive endeavor encompasses around 30 distinct projects, each contributing to the overarching transformation. These projects involve the incorporation of numerous new panels or the meticulous reworking of existing ones, seamlessly integrated into various systems throughout the airport.

The imminent focus lies on the Lobby 8, mirroring the advancements made in Terminal 1, albeit on a slightly smaller scale. As fall approaches, Kasa’s efforts will shift toward the comprehensive replacement of ticket counter software and equipment. This phase also entails the modernization of outdated legacy systems that have faithfully served the airport but are now ready to give way to cutting-edge solutions. These ambitious plans encompass lobbies across the entire airport, ensuring a holistic overhaul that ushers in enhanced efficiency, reliability, and passenger experience.

The Kasa Difference — Work With Us

Kasa stands out due to our unique modularity, making it easy to add or modify components without disrupting the entire system. This feature allows for seamless maintenance procedures without the need to shut down the entire operation.

Our company prides itself on our diverse work in controls and automation, a quality that sets us apart from others in the industry. We not only provide controls and automation for BHS – we are heavily involved in the automotive, parcel/ecomm, grain handling, heavy/industrial equipment industries. By embracing that diversity, we can effectively stay ahead in controls and automation technology.

While we ensure compliance with standards, we also prioritize installation efficiency and post-installation maintenance. We firmly believe that a system’s true value lies in how well it can be maintained over time.

The success of the Honolulu Airport baggage handling system project is a testament to Kasa’s engineering excellence and determination.

When the HNL project is complete, Kontrol Studio upper level will control the entire airport, including both the new outbounds (T1, L8) as well as the reworked and updated existing lobbies (4-7).

By embracing innovation, overcoming challenges, and delivering an open-source upper-level control system, Kasa has — and will continue to — set a new standard for baggage handling systems in the aviation industry.

Although Kasa Controls & Automation isn’t mentioned, local Honolulu news station featured a video on the baggage handling updates on KHON2 and you can see the Kontrol Studio software at 01:50.

Find out how Kasa Controls and Automation can unlock new possibilities for your airport. Contact us today!